Direct-Immersion Cryogenic Treatment Study

Empirical Audio® has been monitoring the dialogue on the web by reviewers and audiophiles concerning the use of cryogenic cooling to treat cables and circuit boards. We were curious as to the effect of direct immersion in LNO2.

It is well known that many metal tools are treated by slowly cooling to LNO2 temperatures and then slowly warming back up which changes their characteristics,some metals in the same way as heat-treating. The tool process obviously requires very special equipment, often capable of lower than LNO2 temperatures. The accounts that we have read with interconnects indicate that only immersion was done and in some cases treatment with only dry ice was claimed to make a positive improvement, albeit short-lived. If there is an improvement, then obviously do-it-yourselfers can treat their cables at minimal expense, although the hazards of working with LNO2 must be taken seriously.

To investigate these claims, we conducted some of our own experiments. First, two identical pairs of 1m cables were assembled, one of which the bare pure silver conductors were immersed in liquid nitrogen for 12 hours (the insulated container also had desiccant in it to dry the air to prevent ice buildup on the conductors prior to immersion).

Results:

The first tests were listening tests. These tests were conducted as single-blind A/B comparisons with the Empirical Audio staff only using our reference system. The results from these were unanimous: that the treated cables sounded like listening through a cotton-filled tunnel compared to the untreated cables. Significant loss of image size and depth was noted. Also the dynamics seemed to be constrained or compressed.

Secondly, we made empirical measurements, including R, L, and C at 1KHz, 10KHz and 100KHz using an hp 4263B LCR meter. These measurements are listed below:

| 1KHz | 10KHz | 100KHZ | Units | |

|---|---|---|---|---|

| L untreated | 1.3 | 1.3 | 1.3 | µH |

| L treated | 1.3 | 1.3 | 1.3 | µH |

| C untreated | 40 | 39 | 38 | pF |

| C treated | 40 | 39 | 38 | pF |

| R untreated | 45 | 46 | 62 | mW |

| R treated | 46 | 47 | 67 | mW |

This result adds fuel to the controversy over whether L-R-C measurements are sufficient to characterize interconnect cables. Based upon this result, we believe the answer is no.

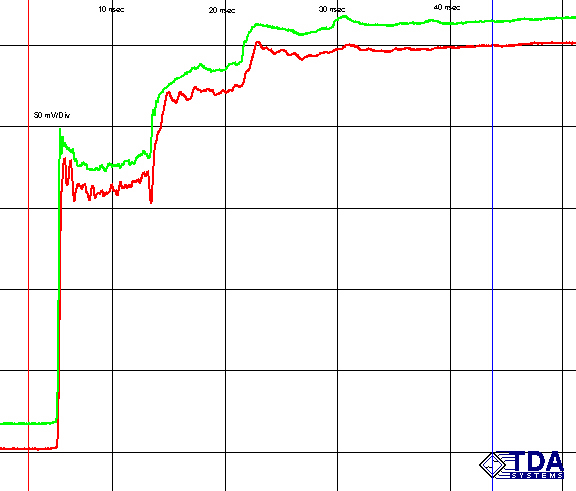

The third set of measurements was a transfer response test, sometimes referred to as a TDT or Time-Domain-Transmission. This is essentially a time-domain measurement of a voltage step with a high slew-rate. The step was generated by an 11801B Tek TDR and the output was monitored by the same instrument. What we are looking for here is differences, not absolute measurements. The resulting waveforms are shown below:

The green waveform is the step voltage emerging from either of the two 1m non-treated cables. Both waveforms for the non-treated cables were virtually identical, so only one is shown here. The red waveform is the step voltage emerging from the 1m treated cables. The two treated cable waveforms were also virtually identical so only one is shown here.

The most obvious difference is that the red waveform has a lot more high-frequency ringing and spikes on it and generally looks more ragged. The waveform of the untreated cable (green) is smoother indicating fewer reflecting boundaries.

There are at least two explanations for this, but here are some possibilities:

The surface finish of the conductors has a lot of micro-cracks that are causing reflections at high frequency. If this is the cause, then there is a strong case for polishing the surface of the conductors.

The crystal lattice has a lot of microcracks, causing reflections at high frequencies. If this is true, then significant damage was done to the metal. The cable bandpass has increased and is causing higher reflections due to more significant impedance mis-match to the 50 ohm instrument cable. The effect that the direct immersion treatment had on the cables may also help explain why ultra-pure metals and single-crystal metals seem to make superior conductors for audio transmission.

Empirical Audio is in the process of obtaining metallurgical photos of sections of the treated and non-treated conductors to gain more insight into the results. Updates to this article will appear when we receive additional information.